Dissolving of Alkanet

Take decorticated and pulverised alkanet and add the interior of Persian nuts. Pulverise these again and add a little lamellose alum. Grind everything together while moistening with water. Make a lump out of it, place it aside and leave it to imbibe colour. Then take a vessel of water, put the lump in the water, stir up and leave it unbroken. Put your finger in and if the colour is beautiful then use it.

At first glance this all seemed pretty straightforward. Alkanet alkanna tinctoria, I could source, although dried and not grown in the same conditions or soil. Persian nuts, after some research, are the humble pistachio. I sourced some non-roasted organically grown nuts so that they would be as close as possible to those available to the makers of the time.

Fig.1. Dyers Alkanet

However, what lamellose meant was not as clear. The only information I could find on this ingredient was that it was a form of alum containing iron. There are plenty of definitions of alum and of lamellose but not in the same context. To replace the lamellose alum I used water that had been laying in a rusty pan for some weeks and added it to the aluminium sulphate in the grinding process.

The recipe states that the Alkanet and Persian nut mixture is to be left to dissolve or mature in water and would ‘achieve a good purple colour’.

In my experience and according to the Maiwa Blog, A Quiet Manifesto, February 2013. Alkanet is not soluble in water alone and any colour is usually extracted by dissolving in alcohol or oil. No mention is given in the recipe to heating the mixture, so would heating make a difference to the final colour? Would the recipe produce a purple colour?

Methods

I decided to use two different methods of extraction for comparison. Suspecting that the water alone may not produce a purple colour I also used an alcohol extraction.

The fibre used was 5gm of homespun white wool yarn and a commercially woven un-dyed woollen fabric. Both were scoured by simmering for an hour with a Ph neutral detergent and then mordanted with Alum at 7% weight of fibre (WOF) in an overnight warm/cool soak.

Two separate dye batches were prepared using 100% WOF.

Batch 1 was prepared using water as the recipe described.

Batch 2 used no water but a strong solution of alcohol.

Both batches were prepared by grinding the alkanet and pistachio nuts in a mortar and pestle together with a little iron water and then letting them rest to ‘imbibe colour’. As the recipe didn’t state a time period for this I put both preparations in ziplock bags and left them for 24 hours.

After 24 hours Batch 1 was removed from the bag and placed in a glass jar with rain water and left for another 24 hours. The liquid showed no signs of colour change so was left for 10 days and periodically shaken to mix the contents.

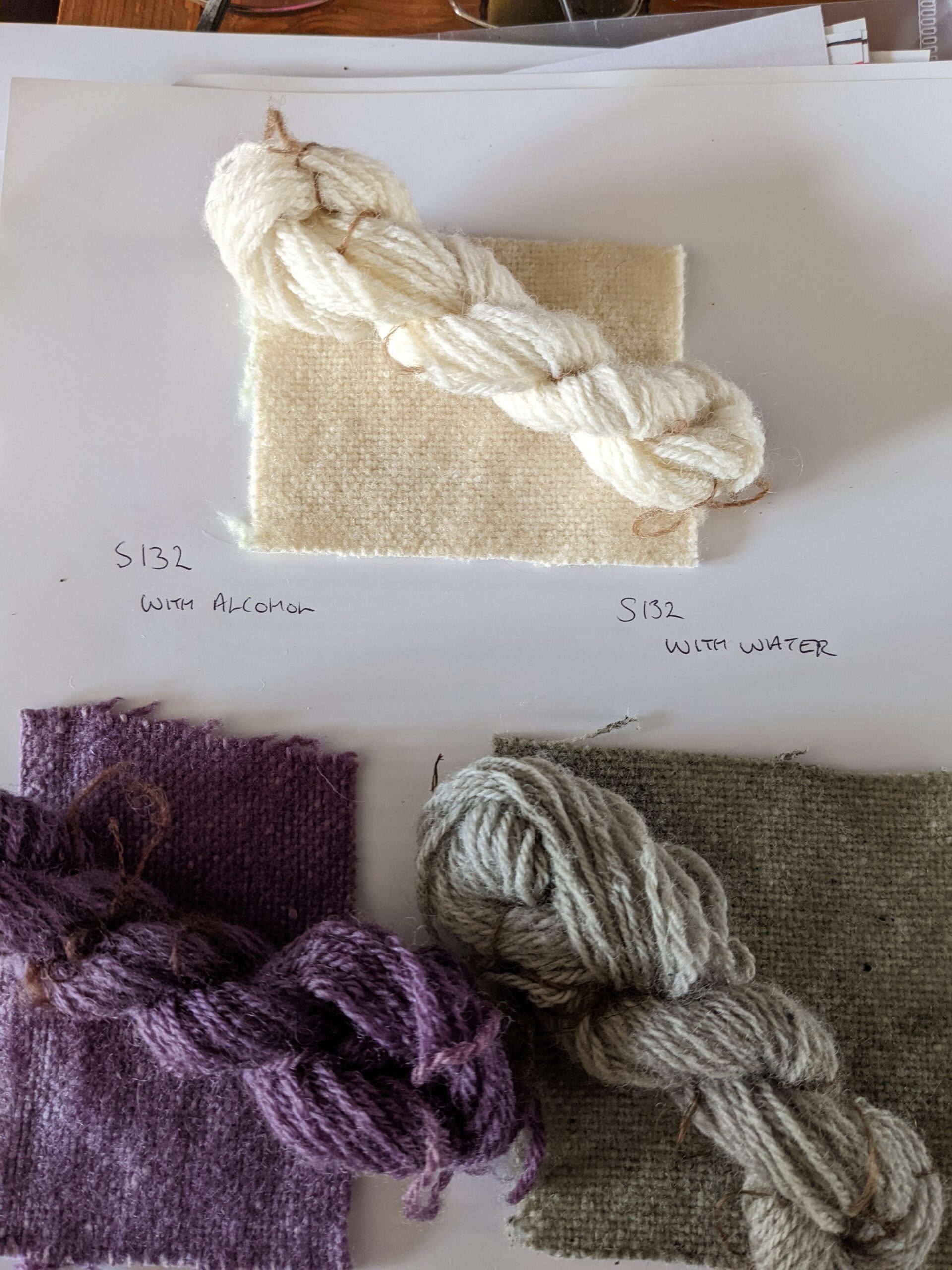

After 10 days the fibre samples were added and left for 24 hours. The fibre didn’t seem to have taken on much colour so I added the liquid and samples to a stainless steel vessel and added a little heat to see if this would aid take up. This proved a little more successful so I brought the temperature up to a simmer and then let it cool for 3-4 hours. The fibre took on a grey/green/blue colour. The fibre was removed from the dye bath and allowed to dry naturally away from direct light. | Fig. 2 Batch 1 before heating |

| Batch 2 ground mix was placed in a glass jar containing alcohol and also left for an initial 24 hours. Although showing colour immediately I treated it the same as the previous batch so I could compare like for like. So it too was left for 10 days and shaken periodically. When the fibre samples were added to this mixture they took on a purple colour very quickly. I didn’t heat this batch of fibres because of the volatile nature of the spirit used and because of the strong colour. The samples were removed after 24 hours and allowed to dry away from direct sunlight. Fig.3 Batch 1 on the right in contrast to Batch 2 on the left with the added alcohol. Samples before removing fibres. |

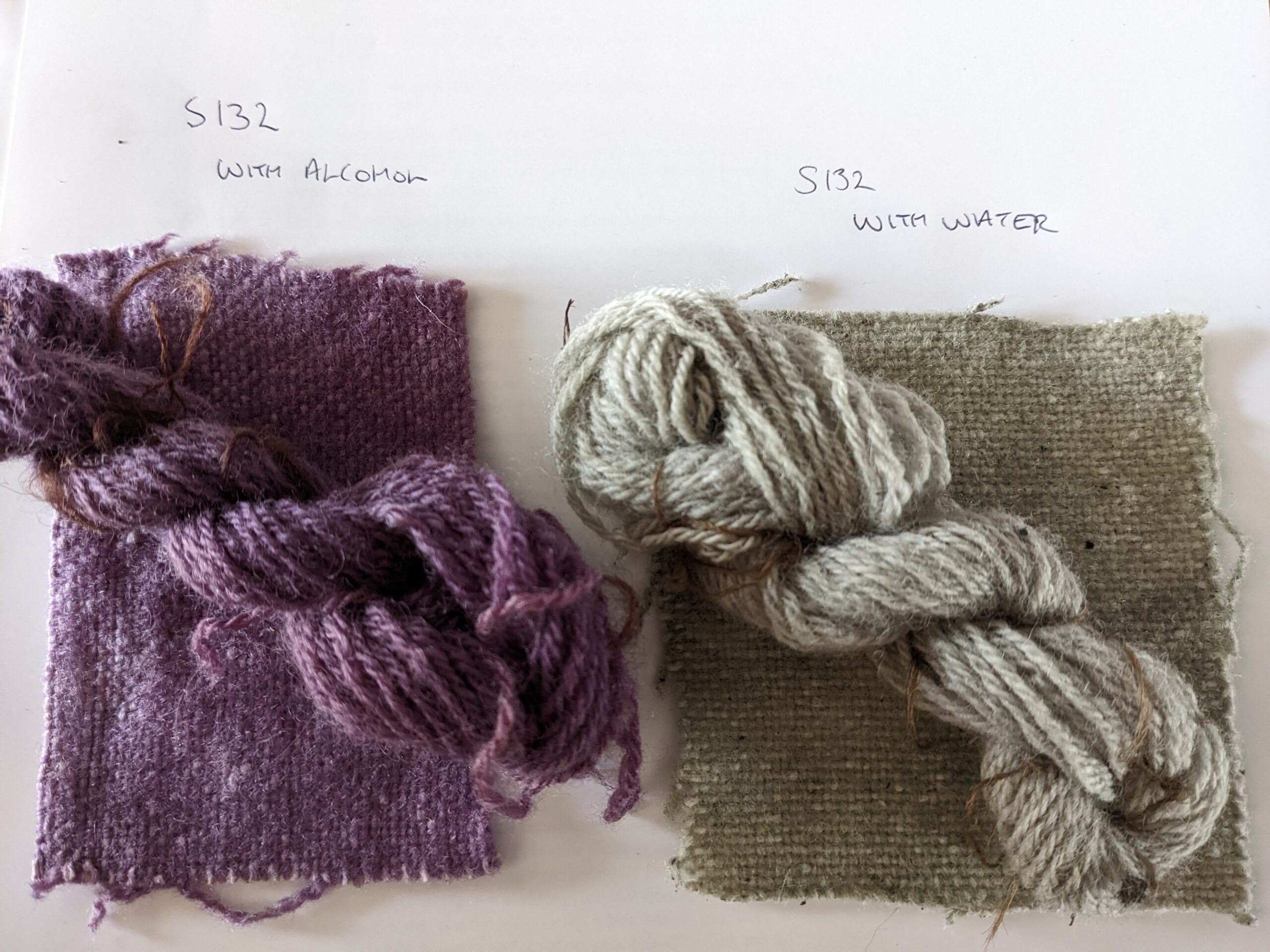

| Colour comparison of the dried fibres from Batch 1 on the right and Batch 2 on the left with an undyed sample above. Batch 1 remained a grey/blue colour very far from what we would call purple today; while Batch 2 is clearly a very rich purple. |

Fig.4 Batch 1 and Batch 2 Comparison:

Batch 1 on the right, Batch 2 on the left of the picture with undyed fibre top.

Light-fast test results

| |

| Both test results were light-fast tested in strong sunlight for 21 days. The bottom half of each sample was covered while the top half was exposed to sunlight for 21 days. Slight fading can be seen on both samples but is difficult to see in the photographs. |

Discussion:

Although purple was achieved it was only on the samples which included alcohol. It is possible that the grey/blue colour achieved with the water mix may have been classed as purple in the time when the Papyri was written but, equally, vital information involving timings and quantities of dyestuff to volume of fluid and conditions may have been omitted by the writer of the recipe because this was such an ‘everyday’ recipe and all quantities were known by all?

Clearly it does produce some colour with water even if it is not the vibrant purple achieved using spirit or oil solvent. I remain to be convinced that the dyers of the time did not know this.

This is one experiment I will repeat as the combined research and experiments from others in our team have provided some interesting results and variables that could possibly push this recipe towards giving a more reliable purple. For instance the ancient Egyptians used aluminium and iron to purify their water which could make a huge difference to any of the recipes in the papyri.

Also interesting is that alkanet ground and steeped in nut oil can make a fugitive purple dye. Maybe I didn’t have enough of the oil and it wasn’t left long enough to ‘cure’?

This would explain the addition of the Persian Nuts (pistachios) in the dye recipe as the oil would act as the solvent for the alkanet before it was added to the water. The nuts also contain tannin which could help to mordant and help fix the dye. As the makers of these dyes would have produced the dye in far greater quantities than was possible for this experiment, the amount of tannin would have been much greater.

Overall a much better result than from the rhamus/rhamnus berries in recipe 113. I will probably recreate this experiment again using a larger quantity of nuts or perhaps acquire some refined pistachio oil to give it a good test.